CNC Pipe Bending Machine: Driven by a servo motor, the bending action is precisely controlled by a computer digital control system, which can achieve high-precision bending.

Hydraulic Pipe Bending Machine: using a hydraulic system to provide power, with strong power and easy operation, it can complete a series of actions such as hydraulic drive, clamping, unclamping, and pipe bending.

Fully automatic Pipe Bending Machine: an automated equipment that integrates an electromechanical hydraulic system. The automatic pipe bending machine control system, composed of a servo motor and its motion control unit PLC, and a touch screen, can independently complete pipe bending and forming, which is suitable for large-scale and high-efficiency production.

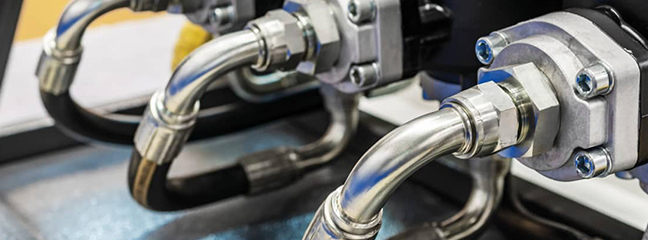

Through the principles of electricity, hydraulic pressure, air pressure, etc., the metal pipe is placed in the mold of the bending machine head, the control button is operated to rotate the bending machine head to the corresponding angle, and the mold on the workbench is acted on by hydraulic or air pressure to make the metal pipe bend and deform.

Mainly includes pipe bending machine frame, bending machine head, hydraulic system, electrical control system, and other parts. Some pipe bending machines are also equipped with mandrels to support the inner wall of the bending radius of the conduit to prevent its deformation.

Preparation: Select the appropriate pipe bending machine model and mold according to the pipe material, pipe diameter, and bending requirements, check the equipment status, and clean the pipe surface.

Pipe clamping: Place the pipe accurately in the pipe bending machine fixture to ensure firmness and precise position.

Parameter setting: Set appropriate bending speed, force, and other parameters according to pipe specifications and bending angle requirements.

Bending operation: Start the pipe bending machine and bend slowly. Pay attention to the deformation of the pipe during the process and control the feed speed.

Quality inspection: After bending, check whether the bending angle, roundness, surface quality, etc., meet the standards.

Subsequent processing: Clean and sort the qualified pipes.

Widely used in power construction, road and railway construction, bridges, ships, furniture, decoration, air conditioning, automobiles, and other fields.

If You Are Looking For Related Products Or Have Any Other Questions Please Feel Free To Contact Us.

At Heshun Machinery, we understand the manufacturer’s requirements for the accuracy and adaptability of the pipe bending process. This is why we customized the HSB-38 NC single-head semi-automatic pipe bender to meet the specific needs of small and medium-sized production operations. By combining intuitive control with powerful electro-hydraulic drive, this model offers reliable and complex bending – from furniture handrails to automotive exhaust components – while minimizing setup time and material waste.

Heshun Machinery specializes in providing high-precision custom tube bending and forming solutions for a wide range of industries around the world.

No.299,Fumin Road,Tangqiao Town,Zhangjiagang,China

+86 189 6229 6262

heshun@heshunjx.com

Copyright © Leading Tube Bending & Forming Machines Manufacturer all rights reserved.